Sustainability at UFlex

The ultimate destination

UFlex is India’s largest multinational flexible packaging and solutions company. The company has created a presence across all verticals of the packaging value chain and is the only fully integrated flexible packaging solutions company in the country with advanced manufacturing facilities in India, the UAE, Poland, Egypt, Mexico, the USA, Russia, Hungary, and Nigeria.Sustainability is not just a component but the very essence of UFlex's corporate strategy. Every business decision is meticulously aligned with the company's sustainability vision and goals.

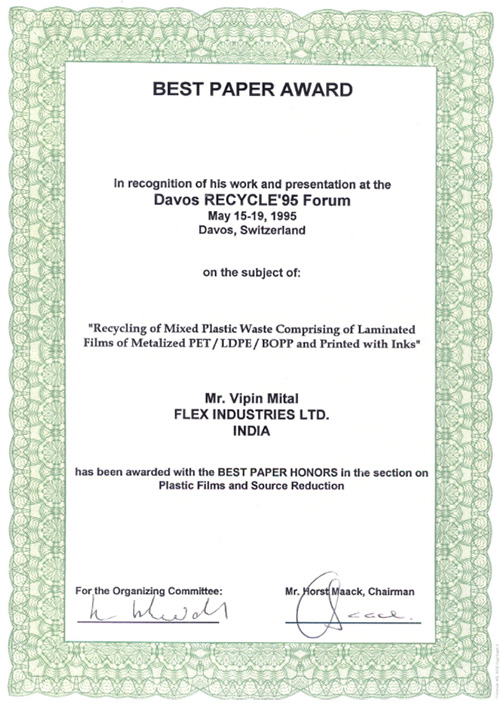

UFlex aspires to achieve net-zero status by 2035, exemplifying its commitment to environmental responsibility since the early 1990s. It is the ‘first company in the world to recycle mix plastic waste’ for which it earned recognition at Davos Recycle Forum in 1995, way ahead of other companies from developed economies.

Strategic Approach:

As an industry leader in building sustainable flexible packaging solutions, UFlex runs a global sustainability initiative called ‘Project Plastic Fix’. This initiative is aligned with the company’s sustainability approach of 4Rs to tackle the challenge of reducing stock and flow of plastic waste in the environment, i.e. - Reduce plastic at source by manufacturing and using films made from PCR | Recycle via upcycling and downcycling of MLP (Multi-Layer mixed Plastic) and PET containers, covers, other articles and bottles | Reuse as source substitution via Pyrolysis | Return to the planet in the form of biomass, if the plastic waste remains uncollected.

Zero Liquid Discharge Technology

UFlex has embraced Zero Liquid Discharge (ZLD), a strategic wastewater management system, that aims to substantially reduce freshwater consumption.

UFlex’s Strides towards sustainable future:

Recycling of Multi-Layered Aseptic Packaging

UFlex has invested in an advanced Enzymatic Delamination Technology to enable aseptic packaging recycling. Enzymatic delamination utilizes enzymes to break down the bonding between different layers of the packaging materials, allowing for the separation of individual layers such as paper and polyethylene/foil laminate which can be reused in the production of new products. UFlex has established a cutting-edge facility for recycling aseptic packaging in Gwalior.

Creating ‘wealth out of waste’ by recycling post-consumer PET Bottles and Mixed Plastic MLP waste

UFlex commissioned two lines in its Noida plants in 2020 to wash and recycle Post-consumer PET bottle and mixed plastic waste collected from Delhi-NCR. The Post Consumer Recyclate (PCR line) converts the post-consumer PET bottle waste to form chips. These PET bottles are crushed, washed and dried to form chips and further upcycled to manufacture UFlex’s range of green packaging film with PCR content called Asclepius™. The Post-Consumer Plastic Recyclate (PCPR) line washes and recycles post-consumer mixed plastic MLP waste and recycles them into granules.

The granules derived are used to form numerous industrial and household products like flower pots, outdoor furniture, bucket, dustbins, paver tiles, road dividers etc. Replicating its efforts in India, UFlex has established recycling plants in Poland and Mexico to process post-consumer multi-layer mixed plastic waste into granules.UFlex recycles close to 30,000 MT of plastic waste in Poland, Mexico, and India and the goal is to reach 1,00,000 MT of recycling by building additional global recycling capacities.