Sustainability practices

Initiative 'Project Plastic Fix': Our Approach to Sustainable Packaging

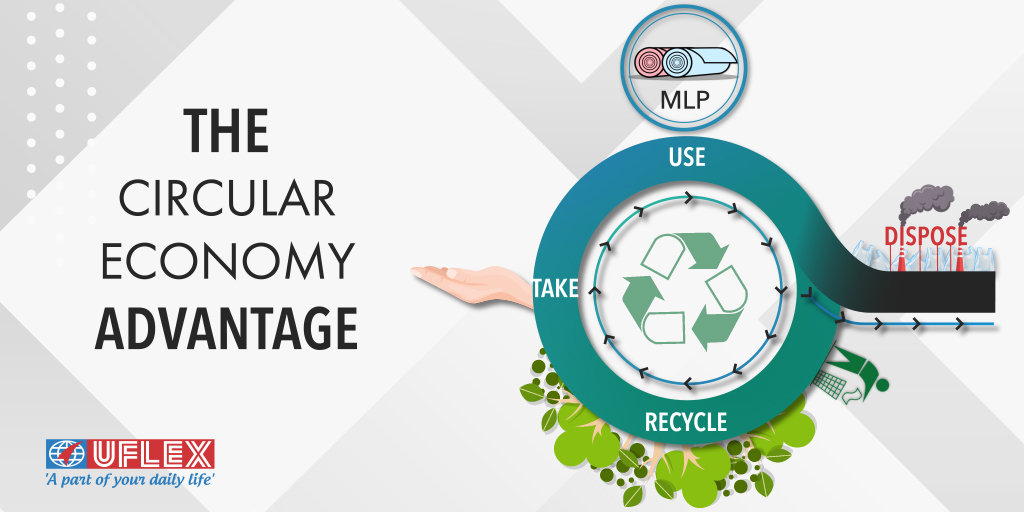

UFlex’ global sustainability initiative ‘Project Plastic Fix’, is designed to form solutions that focuses on solutions to keep plastic in the economy and out of the environment. We aim to manage plastic waste stock and flow through our 4R approach to transform ‘Waste to Wealth’- Reduce | Reuse| Recycle| Return.

To Know More About Project Plastic Fix, Visit Website www.projectplasticfix.com

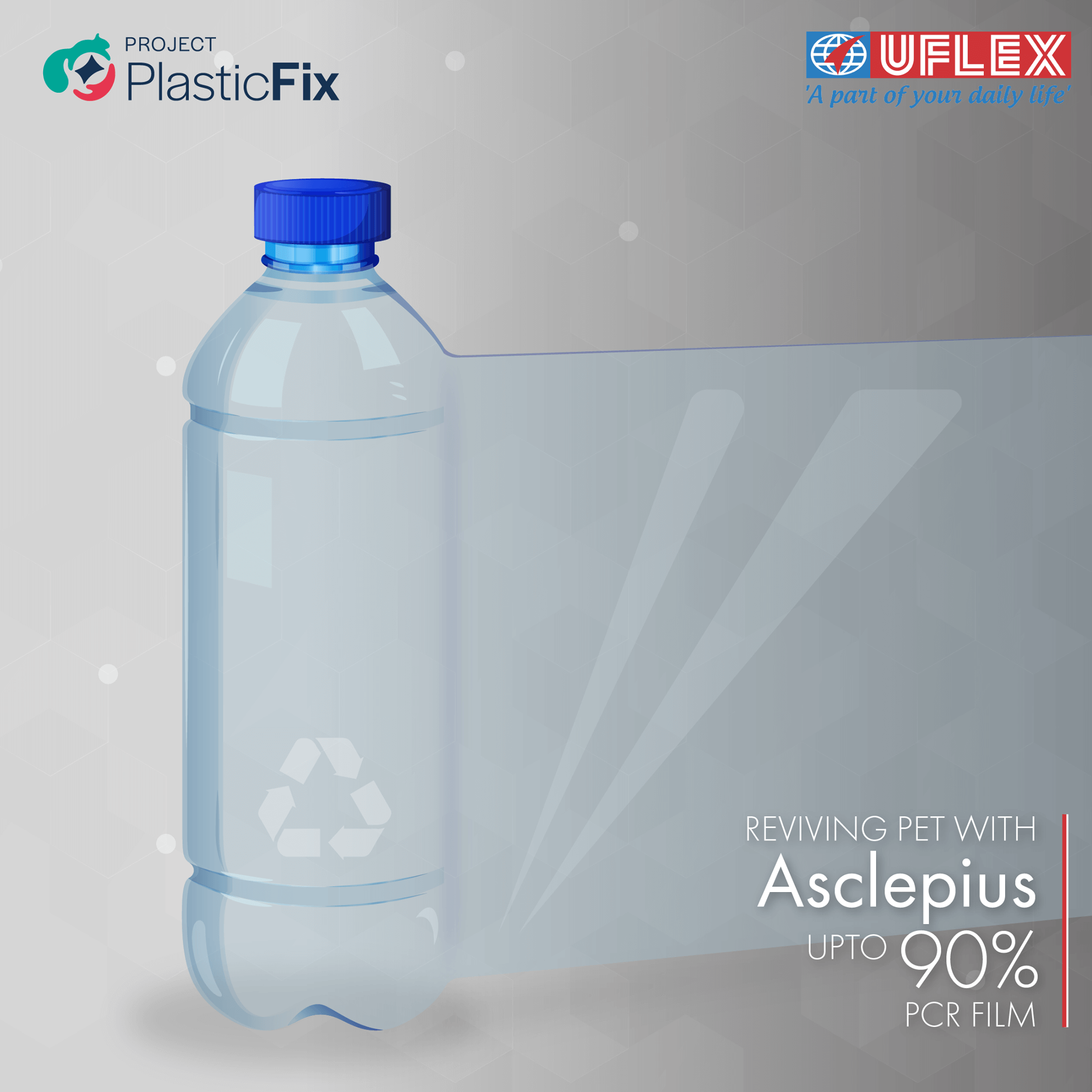

REDUCE | ASCLEPIUS™: UPTO 100% POST-CONSUMER RECYCLED-CONTENT (PCR) BOPET BARRIER FILM

UFlex Group has been a trendsetter when it comes to sustainable innovation and commitment towards the ‘Circular Economy’. It was the ‘first company in the world to recycle mixed plastic waste’ for which it earned recognition at the prestigious Davos Recycle Forum in 1995, way ahead of other companies from developed economies.

Our global film manufacturing arm Flex Films, as part of its commitment towards greener environment, offers an entire range of post-consumer grade PCR Films having upto 100% post-consumer recycled PET content under the brand name Asclepius™. This film’s technology is a family of plain, treated, coated, high barrier and heat-sealable BOPET films based on 100% PCR polymer content. This film represents a 75% reduction in carbon footprint versus virgin BOPET grades yet exhibits the same attributes as its twin substrate.

With Flex’ pioneering technology, an extremely high level of PCR content in the film is being met, as is needed with the accelerating greening demand of the global economy. The 100% PCR BOPET film or PCR film has also received the prestigious ‘Kingfisher’ Certification from SCS Global Services that certifies that Flex Films’ PCR grade films contain minimum 100% post-consumer recycled PET content. This certification corroborates to its customers and to the flexible films’ market, the integrity of its supply chain and claims regarding PCR based film technology. AIMCAL Annual Awards 2019 recognized the film with ‘Excellence in Sustainability’ due to the technology and cost these films offer to the market, followed by a win at WorldStar Packaging Awards 2021 for Food Packaging.

These PCR films come with enhanced sustainability and low carbon footprint and customers have been using these films in a range of packaging and labelling applications in order to help global CPG brands achieve high sustainability goals.

At UFlex Ltd., we have pushed recycling limits with Asceplius Film and have been contributing to reduction of plastic waste on earth, one unit at a time, and create a closed loop ecosystem.

Our range of PCR grade film echoes our aim to reduce virgin plastic use at source and replace it with recycled content. At UFlex, we have pushed sustainability limits with Asclepius™ and have been contributing to reduction of plastic waste on earth, one unit at a time, and creating a closed loop ecosystem

RECYCLE | MLP WASTE INTO GRANULES: MAKING LIVES BETTER FOR HUMANKIND

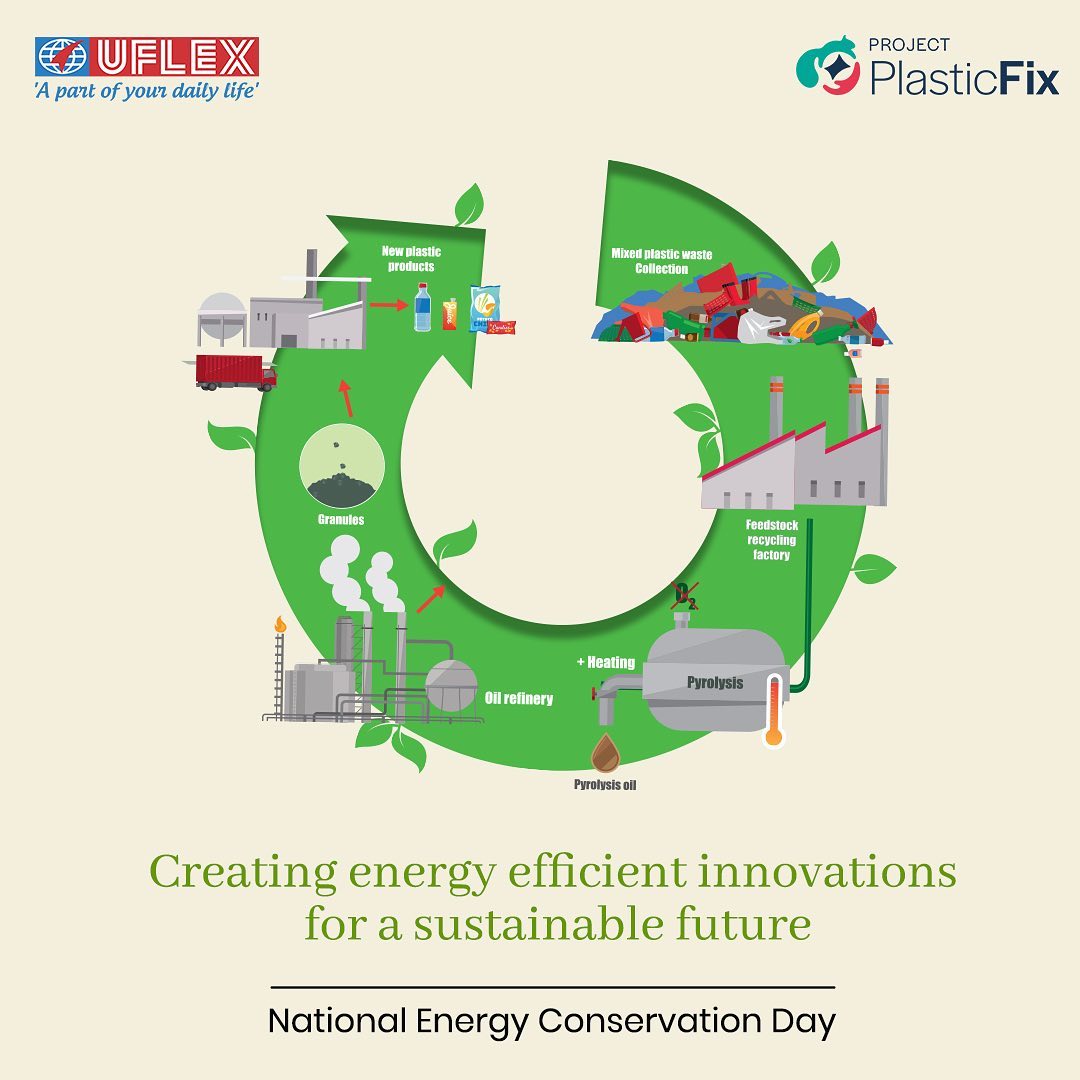

Recycling of plastic waste is the need of the hour. UFlex recognized the need to recycle plastic waste more than two decades back and established recycling units in its plants that convert multi-layer mixed plastic waste into granules. An added feature of the recycled material (granules) is that it is re-used to manufacture industrial and household products like roads, outdoor furniture, paver tiles, dustbins and many more such household and industrial items.

To tackle the challenge of recycling multi-layer mixed plastic waste, UFlex created ReLAM 250, a high-end multi-layer recycling machine meeting European standards, which turns mixed plastic waste into granulated product without the need for separation of layers.

Another major move by UFlex to create wealth out of waste is the introduction of packaging films by upcycling MLP waste into PCR PE films. UFlex won Packaging Gateway Excellence Awards 2020 in ‘Environmental Impact’ for driving the circular economy with its path-breaking technology to recycle MLP packaging waste homogeneously. With all these efforts in place, UFlex is helping create a circular plastic economy and make lives better for humankind.

REUSE | PYROLYSIS PLANT: CONVERTING ITS WASTE PLASTIC INTO FUEL

UFlex’ Pyrolysis is a resource recovery process that converts MLP waste into forms of energy helping the environment clear the plastic waste. At its Noida Packaging plant, UFlex converts discarded plastic waste material that’s generated every day from printing, unused trim, laminates, tubes and other unprocessed material into Liquid Fuel, Hydrocarbon Gas and Carbon Black which substitutes use of energy in machinery.

RETURN | 100% SUPER EARTH FRIENDLY BIODEGRADABLE PACKAGING

An enzyme-based technology, Flexzyme breaks down uncollected flexible packaging waste completely into harmless components like water, biomass and carbon when it comes into contact with soil. The biomass is nothing short of a fertilizer in the natural environment and the technology leaves no polluting impact on the earth while addressing worries attached to uncollected plastic waste. The technology is undergoing trial with some consumer brands currently.

To Know More About Project Plastic Fix, Visit Website www.projectplasticfix.com

Social Awareness Campaign: How to tackle Plastic Waste

17

Sep

While we suggest ‘KNOW PLASTIC’ than saying ‘NO TO PLASTIC’, we are also determined to cleanup plastic waste from our ecosystem. As we observe World CleanUp Day today, resolve to deploy all our efforts that help remove plastic waste from the environment while retaining its value in our daily lives. Lets work together to #reduce #reuse #recycle and #return the importance of plastics in the #CircularEconomy.

13

Sep

UFlex is determined to bring together the community over the shared goal of reducing plastic waste. So, today we are here to share with you one of the solutions to achieve this- Ecobricks! Find out how Ecobricks enable you to turn plastic bottles into reusable building blocks and interesting decor that not just beautifies homes but also saves our planet!

26

Mar

Cricket has taught us some great lessons with the demonstration of how a team can together achieve success and turn things around for the better. Let us show the same spirit of teamwork and collective innings to create a sustainable planet where plastic waste is disposed right, collected and recycled for better use. Lets play the game of sustainability together.

28

Sep

In our quest to create a greener world, our PCR films are created with upto 100% PCR content yet displaying strong barrier attributes. This enables our partner brands to deliver quality packaging while making significant reduction in carbon footprint and achieve higher sustainable goals.

07

Jul

Our responsibility towards the planet & businesses is reflected inside out with our constant innovation and sustainable practices. With our passion for green and clean packaging, we urge more businesses to switch to regenerative practices as well. Let us all move together towards a greener future!

05

Jul

The road to sustainability just got shorter with 20% PCR content MLP packs by UFlex. The latest technology in flexible packaging combined with premium quality and sustainability is now available in India! Same attributes, lesser carbon footprint, elevated benefits to give you a better experience.

13

Apr

A thoughtful start & a useful end for all plastic at UFlex. Efficient use of resources and effective ways to contribute back to the environment go together at UFlex. With our ‘Project Plastic Fix’ initiative, we focus on creating value from plastic waste through innovative techniques.

30

Mar

Sustainability is not a choice anymore but a way of survival. At UFlex, every business consciously works towards contributing to the environment by embedding sustainability in its products and processes thus creating a safe and sustainable lifestyle.

18

Mar

At UFlex, everyday is a Recycling Day! We are making recycling more efficient by repurposing all the plastic used in the process. On this Global Recycling Day, let us look at treating plastic differently and explore our individual ways of reusing and recycling plastic waste.

01

Mar

Converting waste to wealth with its unique processes, UFlex is a trendsetter in sustainable innovation and commitment towards the 'Circular Economy'. Our active and conscious contribution towards reusing plastic & giving it a second life ensures maximum impact in this evolving packaging industry.

28

Feb

Stand Out with your Packaging Choices! When you choose UFlex, you choose the packaging solutions which best fit the bill of value, virtue, ability and sustainability.

24

Feb

Taking away the waste and adding value to it lies at the core of our sustainability approach. We At UFlex recycle plastic waste to create a flow of circular economy and make sure we don’t waste any waste.

10

Dec

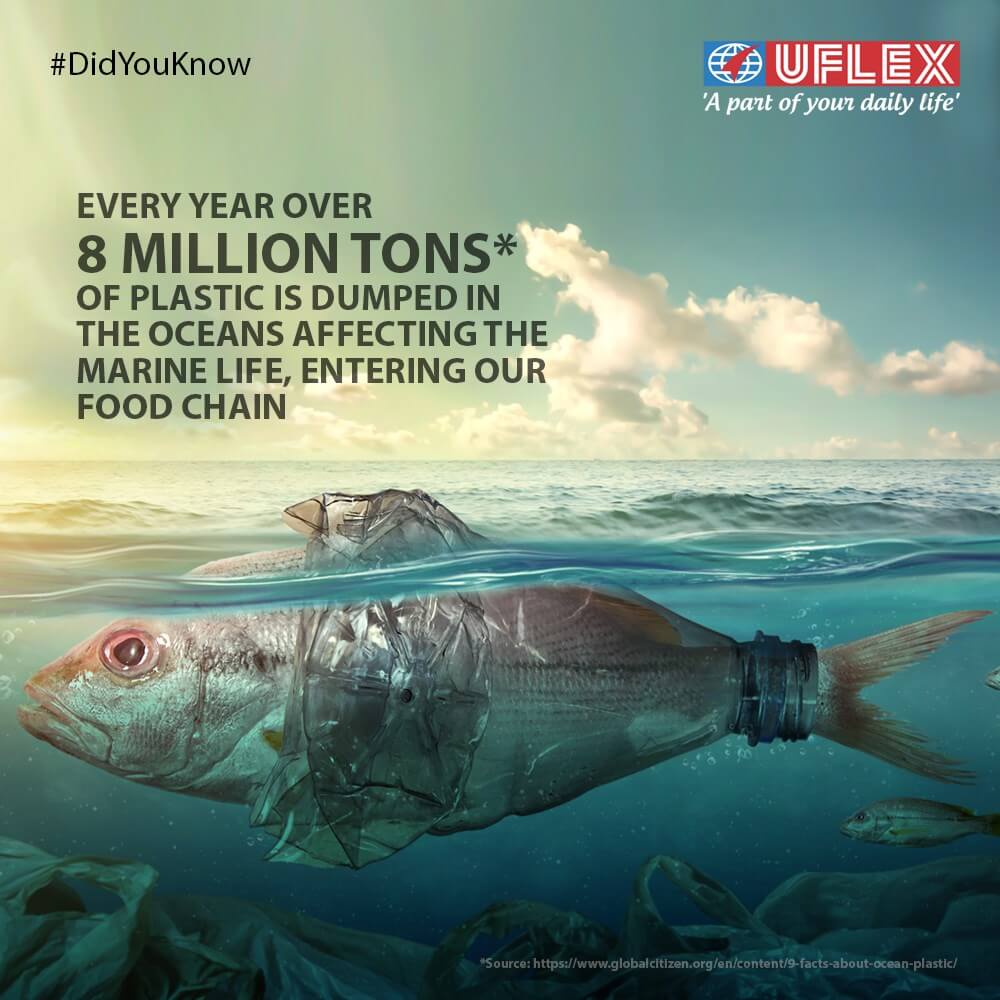

Millions of marine animals are killed each year due to plastic debris in the ocean. Ask yourself whether you want to be a killer or a savior? Act now. Dispose off your waste properly.

27

Nov

One habit can save a lot of habitats. Segregate your discarded waste and make the planet green.

11

Nov

With Project Plastic Fix, UFlex aims to reinstate the virtues of plastic in daily life and put them to better use each time.

23

Oct

COVID-19 has changed our work routine and lifestyle, UFlex urges to bring small changes in discarding the waste that will let you enjoy a better and guilt-free life.

09

Oct

Embrace the journey to evolution. Tread on a path to a better environment around you. Think carefully about how your actions can make or mar the planet. DisposeRight.

31

Oct

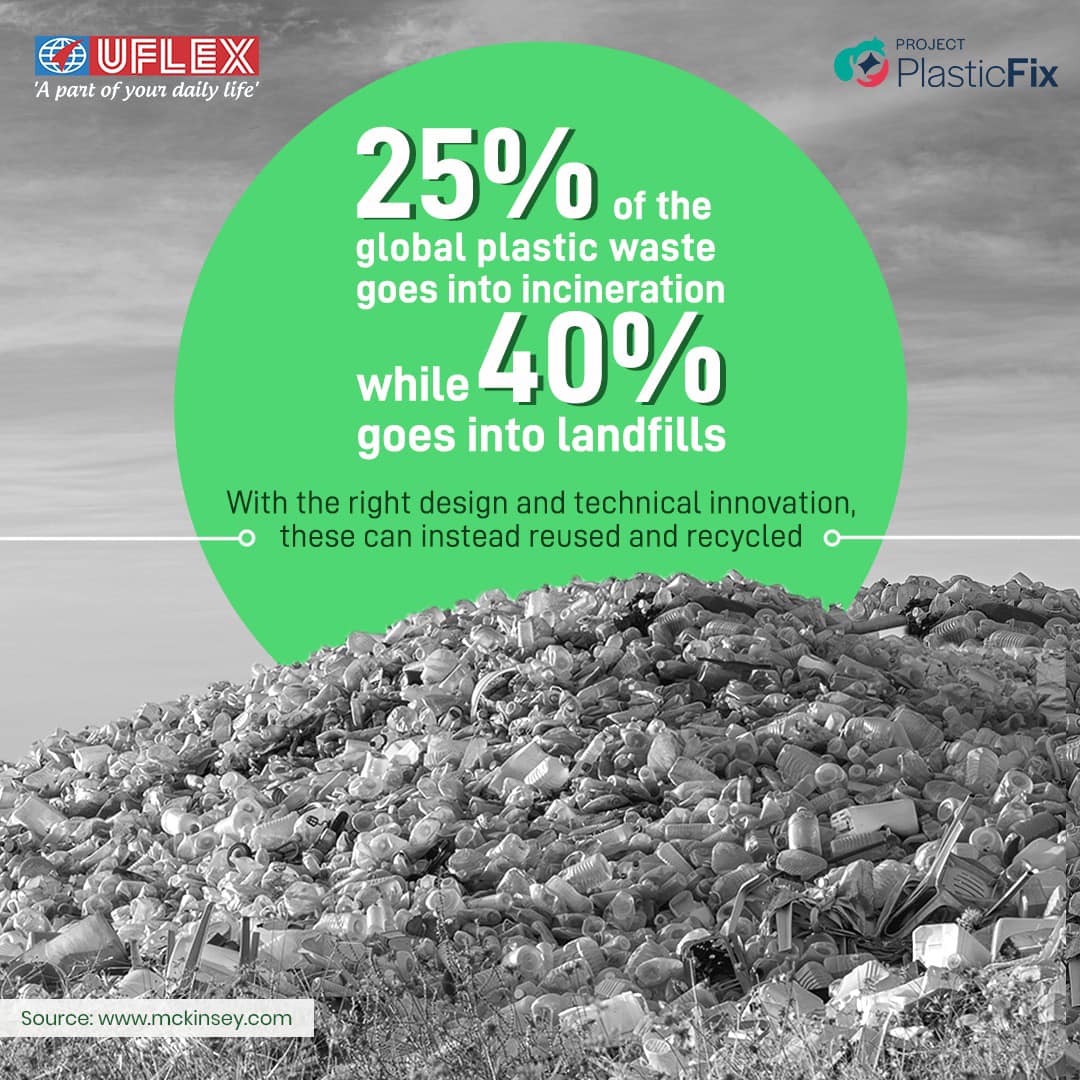

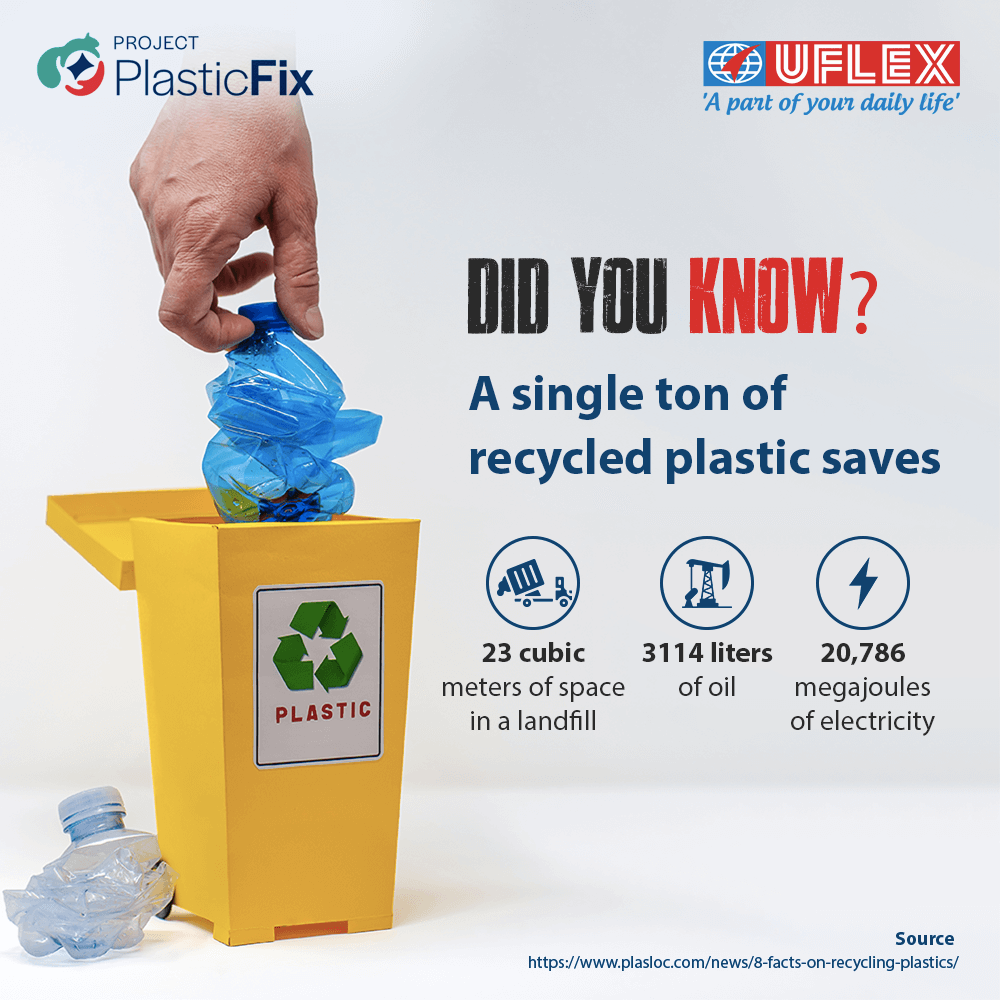

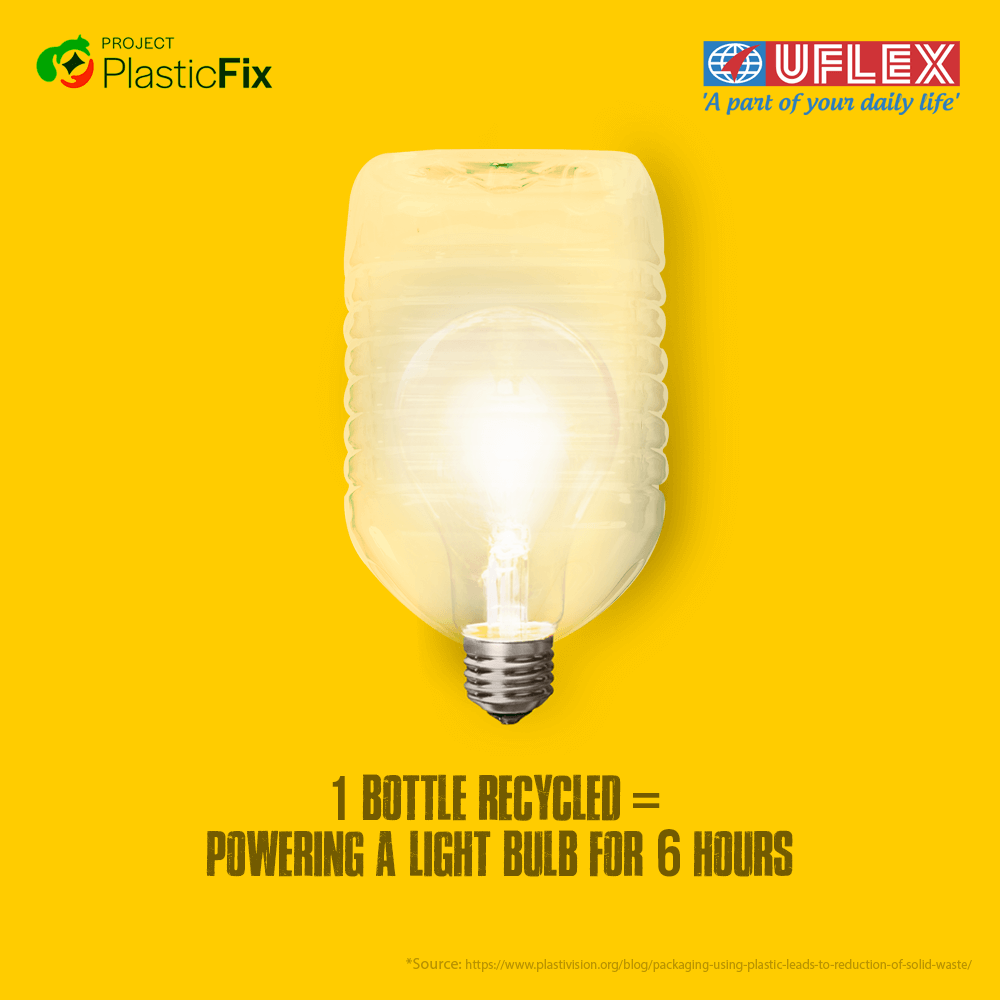

Only a mere 9% of plastic is recycled globally. Together, let's strive to bring this number up to 99% so that existing plastic can be repurposed, creating a circular economy.

26

Oct

The three-way segregation rule can help you contribute to a greener future. Sorting your waste can help us efficiently recycle it and reduce the need to produce fresh plastic.

09

Aug

A step towards a sustainable future is sustainable waste management. At UFlex, we recycle scraps of multi-layer packets to pellets which are moulded into dustbins that help communities effectively manage their waste!

- Flex Films (USA) Inc & Flex Americas S.A. de C.V. are certified by SCS Global for its upto 100% Post-Consumer Recycled (PCR) PET Content Film

- HOW IS MLP SUSTAINABLE -1

- HOW IS MLP SUSTAINABLE -2

- Flex Films (USA) Inc & Flex Americas S.A. de C.V. are certified by SCS Global for its Minimum 90% Post-Consumer Recycled (PCR) PET Content Film

- UFlex conferred with Best Paper Award at Recycle’95 Davos Global Forum, 1995 for Recycling of Mixed Plastic Waste