What’s Trending In Beauty And Personal Care Packaging?

Since ever the world returned to normalcy, there has been a lot of

3 Key Elements to Effective Packaging Design

An average supermarket carries over 40,000 items, creating a daunting task for brands

3 Reasons Why You Should Consider Water-Based Inks For Printing

Water-based inks mark the trend of future of printing to a territory of

Paper Vs Plastic Straws – Which Is Better For Business And The Environment?

There have been constant debates across the world around the use of plastics

Unpacking The Future of Flexible Packaging

If there were binoculars to decode the future of packaging on the trends

Why Brands Must Shift From Rigid To Flexible Packaging

With the growth in consumer needs and other factors such as increase in

Healthcare & Pharma Packaging – Packaging an Enhanced Experience of Sustainability

The purpose of packaging in the life sciences and healthcare industry ranges from

The Importance of The Right Packaging in The Growth of a Brand

The power of proper packaging has significantly risen over time, since as eager

The Challenge of Counterfeiting : What Will Safeguard Brands from Counterfeiting Threats?

The difficulties that ensue from counterfeiting result in a broad spectrum of negative

Aseptic Liquid Packaging- The Undisputed King of The Market, Now Conquering The Post-Pandemic World

Aseptic Packaging is a globally accepted technique for packaging of liquids and semi-solids contents

Packaging Trends in 2022

The year 2021 wasn’t exactly the breath of fresh air many of us

Growing Trends of Sustainability in the Packaging Industry

The role of sustainable materials has grown exponentially in packaging sector. Packaging Industry

Frozen Foods- The Growing Demand and the Innovation in its Packaging

Frozen foods give people a chance to have healthy meals within minutes. Frozen

Evolution of Baby Product Packaging

Modern day consumers are leading fast paced and demanding lives. With them working

KRAFTIKA: Crafting a Sustainable Experience With Paper-Based Tubes

Aligning with our approach to have sustainability as the driving factor behind our

5 Golden Rules for Packaging Innovation and Convenience

The world has changed due to the on-going pandemic. Every industry has to

Circular Economy – An Intangible Approach To A Sustainable Future

The ever-growing population when clubbed with the extravagant demand of goods and products

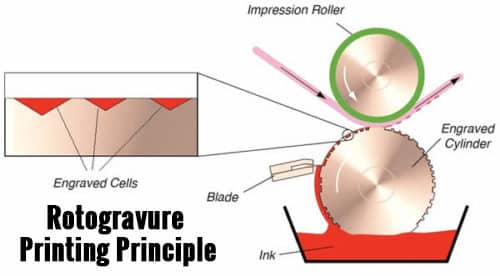

Rotogravure or Flexography Printing?

Picking sides in this case won’t be easy and straightforward!!! Both Flexographic and

Flexible Packaging – The Smarter and Safer Option in Covid Era

Now, more than ever, when the world is undergoing a global pandemic, safety

Importance of Packaging for Online Businesses

With the second wave of COVID-19 pandemic hitting, online businesses are flourishing more