About us

What we do?

UFlex is India’s largest end-to-end flexible packaging materials and solutions company that manufactures a wide variety of flexible packaging films like BOPP films, BOPET films, CPP film, Metalized films, Alox coated films, Speciality films and PCR grade PET films Asclepius, for varied industry sectors across the world.

Since 1985, we have been serving as a one-stop-shop for a multitude of flexible packaging needs in countries like USA, Canada, South America, UK, Europe, Russia, CIS countries, South Africa and other African countries, the Middle East and the South Asian Countries.

With headquarters in Noida (National Capital Region), we have packaging films manufacturing facilities in India and overseas under the company’s global subsidiary packaging films brand ‘Flex Films’ in UAE, Mexico, Poland, Egypt, Russia, USA, Hungary & Nigeria with a cumulative capacity of over 6,09,000 TPA. We are the second largest supplier of thin polyester (BOPET) films in the world for flexible packaging applications. With a host of films being manufactured for product packaging, we are amongst the largest flexible food packaging material supplier in India and overseas.

With our uncompromised quality and service to the customers, we have established an irreproachable legacy over the past few years. In our unspoken yet universal commitment, we believe that all our customers deserve nothing less than the best. The focus on quality innovation emanates from our conviction to deploy advanced technologies coupled with state-of-the-art equipment to add maximum value to our customer’s business.

We incorporate an intricate approach to offer customized packaging solutions to our clientele at competitive pricing in the shortest lead time. This approach has helped us earn some of the esteemed international awards for product excellence and innovation while maintaining sustainable standards.

With an overarching aim to serve our customers by maintaining a close proximity with them, we started our first overseas plant in the United Arab Emirates (UAE). Ever since, there has been no looking back, and we marked global footprints in Mexico, Egypt, Poland, USA, Russia, Hungary & lately in Nigeria.

We assure timely deliveries to our customers that give them access to greater ease and effective working capital management. We stay true to this statement at all times - We are with you, for you whenever and wherever you desire.

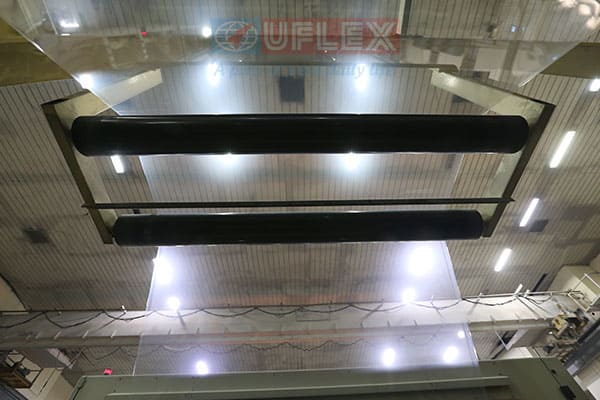

Production Facility

We are a multi-million corporation spread across four continents. UFlex is the only flexible packaging film manufacturer serving varied sectors such as food, beverages, pharma, electronic, industrial products and worldwide packaging market.

We have advanced technology equipped ISO 9001, 14001 and HACCP certified plants producing BOPET (Bi-axially oriented polyethylene terephthalate) films, BOPP (Bi-axially oriented polypropylene) films, CPP (Cast polypropylene) films, Metallized films, Alox Coated films and our upto 100% PCR content PET films Asclepius supplied across Asia, Europe, North America, CIS and Africa.

- Our manufacturing facility in Noida has one line of 6.5 meters and two lines of 6.7 meters each for BOPET films, with a cumulative capacity of 58,000 TPA; two lines of 6.7 meter each for BOPP films with a cumulative capacity of 30,000 TPA; and one CPP line with capacity of 4,000 TPA. Also, we have six state-of-the-arts 2.5 meter wide plasma enhanced high-barrier metallizers with a cumulative capacity of 40,000 TPA.

- Flex Middle East has one ultra-modern 6.7 meter wide Polyester film line to produce 22,000 TPA of polyester films (BOPET); one CPP line with capacity of 18,000 TPA and one 2.5 meter wide plasma enhanced high-barrier metallizer capable of producing 5,400 TPA high quality metalized films.

- Flex America S.A. de C.V’s plant in Mexico produces BOPET films and high-barrier metalized Films. It houses two 8.7 meters wide BOPET film lines to produce collectively 60,000 TPA. It is complemented by two 2.45 meter wide plasma-enhanced advanced high-barrier metallizer with a cumulative capacity of 10,800 TPA; two 1.25 & 1.6 meter wide Alox Coated film line with a cumulative capacity of 7,000 TPA.

- Flex P Films (Egypt) S.A.E. holds four film lines in operation out of which one 10.4 meters & one 8.7 meters wide BOPP film lines that produces 77,000 TPA; one 8.7 meters wide BOPET film line that produces 30,000 TPA and a CPP line that produces 7,000 TPA of film. The film lines are complemented by 10 highly equipped plasma-enhanced standard/high barrier metallizers that churn out 72,000 MT of excellent quality metalized films per year. The plant also houses an Alox Coating line that produces 4,000 TPA of high barrier, transparent film per year.

- Flex Films Europa Sp. z.o.o. plant in Poland was the company’s first manufacturing facility in Europe. The plant houses two 8.7 meter wide BOPET film lines that can produce 75,000 TPA of film supplemented by two plasma-enhanced high-barrier metallizer that can produce 30,000 TPA of films every year.

- Flex Films (USA) Inc’s plant in Kentucky houses an 8.7 meter wide BOPET film line is capable of producing 30,000 TPA. It is complemented by plasma-enhanced high-barrier metallizer that can produce 7,500 TPA of metalized film. The BOPET film line is bigger than any other film line presently operating in the USA.

- Flex Films RUS LLC plant in Stupino houses an 8.7 meter wide BOPET film line is capable of producing 30,000 TPA and one CPP line with capacity of 18,000 TPA. It is complemented by plasma-enhanced high-barrier metallizer that can produce 8,000 TPA of metalized film.

- Flex Films Europa KFT which commissioned in 2021 houses a 10.4 mt wide BOPP line with a capacity to produce 42,000 TPA. This is UFlex’ first BOPP line in Europe thus giving the company an advantage of offering a mix of BOPP films from Hungary plant and BOPET film from Poland plant to serve its patrons in EU region.

- Flex Films Africa Pvt. Ltd. commissioned in 2021 houses a 10.6 mt wide BOPET line with a capacity to produce 45,000 TPA. This is UFlex’ first-of-its-kind 10.6 meter wide BOPET line and the facility also houses two state-of-the-art 2.5 meter wide plasma enhanced high-barrier metallizers with a cumulative capacity of 15,000 TPA.

- UFlex manufacturing facility in Dharwad commissioned in 2022 houses a one CPP line with capacity of 18,000 TPA and one 10.6 mt wide BOPET line with a capacity to produce 45,000 TPA. Also, we have Two 2.9 and One 3.3 meter wide plasma enhanced high-barrier metallizers with a cumulative capacity of 30,000 TPA.

Operational Excellence

We specialize in designing solutions with immaculate precision to maximize our client's operational economy and bottom line.

IN DOING THIS WE PARTICULARLY FOCUS ON:

- Path-breaking innovations with differentiation;

- High material efficiency leading to greater production yield;

- Reduced operating cost;

- Optimum asset utilization.

We continue to work towards world-class operational excellence by methodical elimination of losses in each area of operation. The focal point incessantly lies in sustainability as we progress to reduce plastic waste and create materials that are recyclable, biodegradable and non-fossil fuel based.

Research & Development

The trend towards shift from rigid packaging to flexible packaging for a lot of consumer brands, mainly on account of attractiveness, consumer convenience, cost-effectiveness and strength, has generated a lot of demand for flexible packaging films. The segment led by demand for food packaging films is the fastest-growing sector globally. India’s packaging industry is no exception. As suppliers of food packaging, its films as well as food packaging machine domestically and overseas, UFlex has witnessed a rising graph continuously. To create its USP in the sector, the Packaging Films Business has a dedicated Research and Development department located in India & USA each that focusses on constant innovation.

The prime thrust at Packaging Films Business of UFlex is to develop and customize products as per clients’ requirements and carry out a viability analysis for their benefit.

With our predominant and unwavering focus on developing essential skills, led by well-defined roadmap, we identify and mark the requisite resources for efficient implementation and concentrated attention to achieve desired results. This has been the key to our consistently good track record of new and developing cutting-edge products and requires complete dedication and a never-say-die attitude.

To Know More About Packaging films, Visit Flex Films Website www.flexfilm.com